| Author |

Topic Topic  |

|

AAA

49 Posts |

Posted - 19 Sep 2021 : 09:20:13 Posted - 19 Sep 2021 : 09:20:13

|

D-POST AND REAR ROOF TRIM

Not something I have done recently, but something I made when I first bought the car! I thought this might be worth including as it is often a problem in most Rapiers, (although not fastback Alpines as they don't have the same trim).

The padded trim above the rear seat is often in poor condition. In my car it was badly misshapen and breaking up. The original trim was made up of a hardboard backing, covered with a type of hard foam and covered in thin vinyl. I suspect these were made in a vacuum press. Very early cars had a slightly different, (but similarly problematic) rubberised version.

I used the original trim as a pattern and cut three sections of hardboard. I fitted the side pieces to the car using the original clips. I soaked the ends of the top section in boiling water and bent this roughly to shape. When I fitted this I found the hardboard had shifted slightly when being bent, so modified the paper template and tried again. Once I had the hardboard sections fitting well, I removed them from the car. I added a sheet of upholstery foam to each and stapled black vinyl over them. At the rear, (and front of the side sections) I folded the vinyl over on itself and used this overhang to tuck behind the glass seals to finish the edges.

These parts have now been in the car for well over twenty years and still look good. I might make some slight changes to the side pieces to neaten up their front edges a little, but this will be once everything else is finished.

|

|

|

|

Commerlad

United Kingdom

50 Posts |

Posted - 18 Sep 2021 : 21:22:45 Posted - 18 Sep 2021 : 21:22:45

|

You could find the glue you have used on the vents is harder to undo than the cyan-acrylate.

Which can be easily separated by immersing in hot water.

Sometimes I think laterally, but then I have to get up! |

|

|

|

AAA

49 Posts |

Posted - 17 Sep 2021 : 19:21:52 Posted - 17 Sep 2021 : 19:21:52

|

CENTRE CONSOLE

When I bought the car, it still had its original centre console. The side strips were missing, (these get hit repeatedly by the seatbelt buckles every time the seat is tipped forwards) and the aluminium surrounding the gear stick was held down with rusty screws. I removed this and fitted a black plastic version from a scrapped 1969 H120. This has now been in the car for over twenty years.

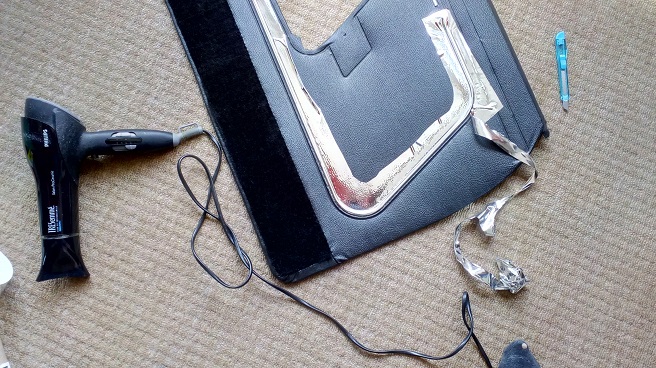

I put a request out through the forum earlier this year for a replacement of the correct type. I was offered two, a green one from an automatic car with most of the aluminium trim present, and a black one from a manual car with very little aluminium trim, but the correct piece to fit around the gear stick present. I stripped both down, and used the black plastic base as a starting point.

The green console being taken apart.

I cleaned up the back plastic base, then gave this a rub over with back shoe polish. I spent some time knocking dents out of the aluminium sections and side strips, (each side trim took around an hour to get straight and remove all of the dents). Each part was then cleaned and flatted using various grades of wet and dry paper and soapy water until a suitable finish was achieved. I used matt black stripe tape, (as was done originally) on the centre of the side trims. I had one piece of aluminium missing, (the piece on the back) so this was made from new 0.8mm aluminium sheet and faced to match the rest. I made new staples for the side strips using staples from the staple gun and reshaping them. The staples were sprayed matt black and the strips fitted with the staples, bending the ends of the staples outwards on the underside. Interestingly, according to the parts book any replacement side trims bought new as service replacements came with self tapping screws!

I made a new padded base for the cubby from plywood, foam and black vinyl, (the original has a hardboard backing). I also made a new gaiter for the gear stick on the sewing machine by copying the holed remains of an original.

The aluminium surrounding the gear stick is held in place with three strips of aluminium underneath attached with epoxy resin. Over time these come adrift and the aluminium lifts upwards, (especially when selecting first and third gear). I refitted the aluminium using the original method, but I also added a long self-tapping screw through the inner edge of the black steel surround at the base of the gaiter. This runs tight under the plastic base towards the front ashtray. This should add strength and stop this problem.

I bought a new cigarette lighter socket and fitted this, adding my original cigarette lighter. I had several old sockets, but these were all corroded. There are several new illuminated ones available with a bigger diameter than ours. The illuminated ring is easily removed, giving a socket identical in size and appearance to our original ones.

I put the console to one side. This will be the last piece to fit to the interior.

|

|

|

|

Panky

United Kingdom

70 Posts |

Posted - 16 Sep 2021 : 20:50:50 Posted - 16 Sep 2021 : 20:50:50

|

| Even on close inspection that is superb. |

|

|

|

AAA

49 Posts |

Posted - 16 Sep 2021 : 19:19:37 Posted - 16 Sep 2021 : 19:19:37

|

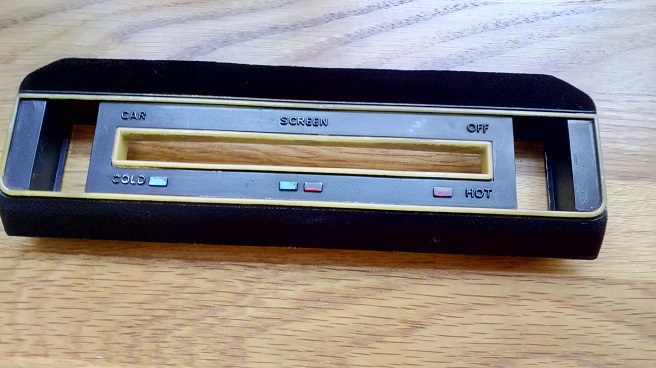

HEATER CONTROL PANEL (AND INSTRUMENT SURROUND)

I had painted the original heater control panel years ago. This had some damage on the corner, and where one of the controls had rubbed. I had another panel amongst my spares, so started with this.

I sent the panel to the same company who had successfully refinished the vents. They offered to paint the black after refinishing the chrome sections too! After about six weeks I began to worry, so contacted the company. They said that they needed a couple more days on the part, and would then return it. When it arrived home I was very disappointed!

The chrome areas were fine, but the black areas were not! The chrome process had left several runs. These had been painted over using a semi-gloss black paint (which highlighted the problems) and the masking had not be done to an acceptable standard. I put the part to one side and carried on with other jobs.

After a few weeks, I decided to try to improve the part. I firstly bent the end of a tapered needle file slightly upwards to reduce the risk of scratching, and after masking the chrome areas, used this to remove the worst of the runs. I then used wet and dry paper with plenty of soapy water to flat the black areas. This process took the majority of an afternoon to achieve a suitable surface.

After carefully masking the chrome areas, I airbrushed the black areas using many thin coats of matt black paint, flatting as necessary until a suitable finish was achieved. For the detailing I used Humbrol model paints and a good quality code 000 brush. For the lettering I used Humbrol satin white 130, applying three coats. The S in Screen was the biggest challenge, as the definition of the moulding here had been mostly lost by the chroming process. For the red I used Humbrol 174, paying particular attention to the corners and making sure the sides of each block were parallel. For the blue, (which is a particularly distinctive shade) I found Humbrol 89 to be the closest match.

I am happy with the result! For a while, I though this would not be salvageable! I wouldn't put another heater control panel through this process. The parts are too rare to risk, especially when considering the cost of the process. I think I have (just) managed to get away with it!

I am lucky that the instrument surround on my car has the majority of its original vacuum metalising intact.

I have found a company in America who claim to be able to refinish our instrument surrounds and heater panels to at least as good as factory standards. If I can get hold of another heater control panel and an instrument surround I will send them off and see what they can do! I have had several over the years, but have given these away to other club members. Ideally I need ones which have not been overpainted, but will consider any I can get. This is because heavy previous abrasion to the surface, or the use of certain paints even when removed may make them unsuitable for the process apparently, (I don't want to pay to send the parts to America, only to have them returned). If you have any you are willing to part with, please send me a PM, I would be most grateful!

|

Edited by - AAA on 20 Sep 2021 07:45:14 |

|

|

|

828CC

United Kingdom

55 Posts |

Posted - 15 Sep 2021 : 20:54:57 Posted - 15 Sep 2021 : 20:54:57

|

| Your dedication and ingenuity are to be admired... Many thanks for sharing with us.. |

|

|

|

AAA

49 Posts |

Posted - 15 Sep 2021 : 19:19:41 Posted - 15 Sep 2021 : 19:19:41

|

DASHBOARD VENTS

The dashboard vents are held in place with two screws. These can be easily removed after pulling the air hose off the back.

The first job was to remove the eyeball part for refinishing. Two types of socket were used. Early cars have a pressed steel socket, held together with two rivets. Around 1970 these were changed to a plastic socket which twists together over two plastic lugs. The plastic type were glued using cyanoacrylate at each lug. The steel sockets are easy to dismantle by drilling out the rivets. The plastic type can be separated by carefully inserting the tip of a thin knife under the plastic around the lugs and cracking the glue, care is needed here to avoid breaking the plastic! I tried various methods to separate these.

An early-type vent out of my collection of spares.

A vent socket out of my car.

Once the eyeball part is out the butterfly valve can be removed by unscrewing the two small screws from each end of it and pulling the valve out to the rear. The central knob is held in place using a recessed star washer. This is hard to get at. I used a curved needle, prising up each tab in turn and working around, slowly walking the washer off the knob spindle.

The eyeballs and control knobs were originally vacuum metallised. There are several companies in the UK offering this service, but having contacted most of them, they are only interested in new parts and runs of hundreds! I have previously tried using chrome spray paint, but never found this satisfactory. I have tried various approaches with this - thin coats, thick coats, over-lacquering... nothing seems to give a suitable finish!

I found a company who uses various chemicals, (one containing silver nitrate) and repeatedly floods the surface with these. 99% of the material that sticks to the surface evaporates! This gives a tough, mirror chrome finish. The cost of this process is relatively high! I sent the vents off, several weeks later they returned.

The finish is excellent! The knobs no longer fitted due to the thickness of the finish, but a little attention with the needle files soon had these back in place. I put the vents back together. The eyeballs were quite tight in the sockets, partly due to the slightly thicker finish and partly due to the felt rings in the sockets having swelled due to me washing them! Once together I used two small blobs of epoxy resin in the spaces at the ends of the lugs to stop the sockets twisting apart, rather than using cyanoacrylate. This should be easier to remove when taking the vents apart in the future by chipping or drilling out as epoxy doesn't run into the joint. The vents have been in the car for a few weeks now, and have loosened up nicely as the felt has compressed back into place!

|

Edited by - AAA on 19 Sep 2021 08:54:21 |

|

|

|

Laceyspacey

United Kingdom

12 Posts |

Posted - 15 Sep 2021 : 16:59:12 Posted - 15 Sep 2021 : 16:59:12

|

Some great tips here thank you I will buy some of that webbing for my front seats......

quote:

Originally posted by AAA

FRONT SEATS

I had managed to get hold of four front seats. All had damaged covers and failed rubber diaphragms. One seat had been professionally repaired at some point in the past, with some parts replaced with a different type of vinyl.

I stripped all four seats back to the frames. The frames were rusty and the foam cushions were breaking up.

I selected what appeared to be the best pair of frames. These were de-rusted and cleaned back to bare metal. I found one frame to be cracked, so this was welded. I then sprayed the prepared frames with anti-rust primer, black primer and several coats of black satin finish Hammerite.

All of the covers were damaged. I unpicked most of the stitching and used sections from all four seats to make up a full set of covers. I cleaned and repaired any slight damage on each section before stitching everything together. I strengthened the edges of the covers, (where they are clipped over the frames) using a pre-glued iron-on fabric tape. Making up the covers was a slow job, taking a number of evenings to complete.

None of the seat foams were useable. They were leaving crumbs, were hard and brittle in places, and were covered in old glue. I bought new 6" thick blocks of high density upholstery foam, choosing a foam which was slightly firmer than the original, (as I suspect the originals have lost some of their structure).

Using the best survivors as templates, I marked out the shapes with a felt pen, making the new foam slightly bigger but also measuring the insides of the covers to be sure. Using an electric carving knife I cut the foams roughly to shape, being careful not to remove too much material.

The foam was then finished using a large box cheese grater, (finest side) and a rubber-backed fine sanding disc in the electric drill. I tried using a coarse sanding disc, but this had a tendency to grab and snatch at the foam. Each foam took about two hours to shape from start to finish.

I replaced the seat diaphragms with Pirelli webbing, (the wider 2" heavy duty type). I made use of as many existing holes in the frames as possible so as to limit how many additional holes had to be drilled. I used a gasket punch for the end staples to ensure a neat hole in the webbing and reduce any chance of the end staples pulling through. The straps have to be made shorter and stretched into position.

Originally, the seats were assembled using large quantities of glue. I reassembled them using glue only where necessary to make them easier to repair in the future. I avoided using glue on the covers, pulling the shaping in using loops of thread passed through the seat foams and tied behind through thin plastic spreader plates. These are hidden behind the Pirelli straps. I replaced all of the four-prong cover retaining clips with a two-prong type, again making it easier to take the seats apart in the future. These also do much less damage to the edges of the covers when removed.

According to the workshop manual the seat runners cannot be taken apart for service and repair, this isn't true! By bruising down the pressing on the inside of each runner at the back, they slide apart. Inside each are two steel rollers, each with two rubber tyres. I cleaned these up, removing a lot of dirt and old grease. When reassembling, grease only needs to be applied to the sides where the rollers can rub and the very edges of the top runner, the rest can be left dry. The various plastic knobs and lever finishers were cleaned, with any roughness or scratches removed using abrasive paper. These were then polished and refitted. I put the seats to one side rather than fitting them to the car so as to make it easier to work on the dashboard.

|

|

|

|

AAA

49 Posts |

Posted - 13 Sep 2021 : 19:05:30 Posted - 13 Sep 2021 : 19:05:30

|

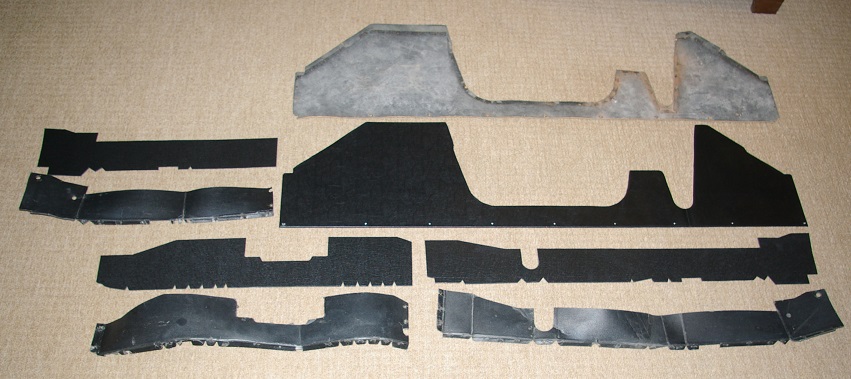

FRONT PARCEL SHELF

I had made a replacement parcel shelf when I first bought the car, but I was never completely satisfied with it! The folds on the back section weren't as neat as I would have liked, and it had broken up around the steering column and warped over the last twenty-odd years.

The original shelf has a faced hardboard base with faced millboard at the back, held together by rivets and staples. Millboard is available from both Woolies and Martrim, and although it looks the same as the original material, it is about twice as thick.

I started by taking a ruined factory-original shelf apart. I used the pieces as templates to firstly cut the millboard sections for the rear of the shelf. The millboard is very tough! A jigsaw does not leave a neat edge, so I cut through it using a Stanley knife. Each cut took eight firm passes with the knife. The tip of the blade wore out quickly, so I replaced the blade several times.

When I attempted this years ago, I had used hardboard for the base. This time, I used birch three ply, covering this with black vinyl folded over the front edge and ends but cut flush with the edge of the plywood at the rear.

On my previous attempt, I had scored the millboard to create the folds, but I was never happy with the result. The original millboard appears to have been put in a press of some sort to stretch the material at each bend. I experimented with offcuts, trying various methods to create the same effect. For the forward bends, (all of the vertical folds other than the one each side of the steering column) I finally settled on using a steel bar and two pieces of softwood in the vice. I found that by clamping the bar and millboard between the pieces of wood, winding on 3/4 of a turn on the vice created a suitable dent in the rear of the millboard without damaging it. With the bar removed, I positioned the millboard between the blocks of wood at the position of the centre of the fold and gently worked the material over. This created a neat bend with no damage to the front face. I used the same method for the bends at the end of the shelf where the material bends up under the ends of the shelf.

The rearward bends were more of a challenge! I tried the same approach using the bar, but any attempt to work on the front of the material left unsightly marks. It also caused the material to delaminate wherever it was near to the cut edge. There is a rearward bend all the way along the bottom of the back edge, and either side of the steering column, (these bends are especially close to the cut edge, with only a very narrow strip of millboard between the fold and the column).

Next I tried using a small cutting disc in the rotary tool to create a V-shape cut out along the back of the fold, but this was inconsistent in depth and created a lot of smoke. I finally settled on a 90 degree v-shaped router bit, fitted in the pillar drill with the table wound up. With newspaper taped to the drill bed to protect the front face, and after several trials to determine an appropriate cut depth and method, I passed the millboard freehand through the drill, cutting a v-shaped groove along the back of each fold. This method worked well, leaving a cut of consistent depth. It left slightly fluffy edges, which bothered me initially, but these turned out to be beneficial later on.

The cut is about half way through the material. As the material is twice the thickness of the original, it should be at least as strong as the folds on an original shelf at this stage.

Having cleaned up and repaired a couple of splits and rubs to the original padded rail, I riveted this to the base of the shelf, but left the back off. I fitted the base and rail to the car, and using a setsquare and masking tape, accurately marked the positions of the steering column and radio so as to position the back as accurately as possible.

With the base removed from the car, I started to fit the rear sections. Each was held in place, drilled through and pop-riveted from underneath the shelf, using a washer on the back of each rivet. I did most of this on my own, but it would be much easier with a second pair of hands! I took extra care to make sure the cut outs for the radio and steering column were in the correct places.

As a final step, just to be sure I ran a bead of neat PVA glue along the entire fold at the back of the shelf, into the v-shaped groove. The fluffy edges here helped to absorb the glue and tie the edges together. I did the same down the back of the grooves cut for the folds next to the steering column cut out. This was then left to dry overnight.

All visible rivet heads were sprayed matt black before fitting and touched in after fitting where the rivet gun had rubbed the centre of each. I used 4mm x 12mm aluminium rivets throughout with spreader washers. The finished item is extremely rigid!

|

Edited by - AAA on 16 Sep 2021 11:12:47 |

|

|

|

AAA

49 Posts |

Posted - 11 Sep 2021 : 19:56:03 Posted - 11 Sep 2021 : 19:56:03

|

GLOVE BOX

The original glove boxes are made of millboard held together with bifurcated rivets. Mine was tatty and out of shape. I considered using the hot water and clamping approach followed by a vinyl paint finish, I also considered making a new one from millboard, (more on millboard later). I ruled both of these ideas out, deciding to try to improve on the original design and construction.

Amongst the various parts I had collected was a wrecked glove box, with a large tear in it, (so it was not really of use to anyone). I pulled this apart and laid it flat to use as a template. I cut fresh material from sheet steel, folding this to the correct shape. I plug welded this from behind, forming a (very) rigid structure of the correct shape and size. I sprayed this matt black. I applied a sound deadening pad to the back.

For the interior, I used a special black-coloured glue and fine nylon flock. Once this was completely dry I vacuumed it out, leaving a smooth and soft surface. I riveted the original metal rail onto the front edge. As my car is a relatively early fastback, it originally had the larger glove box lamp with glass lens and chrome hood, (from around 1972 these were replaced with a smaller lamp with exposed bulb and no lens or hood). My original lamp was hanging out as the rubber had perished. Fortunately, some years ago I had bought a replacement from Speedy Spares but never fitted it. I fitted this to the new glove box.

As the glove box lid was out of the car, I removed the inner metal section complete with hinge. This was sprayed satin black. I also sprayed some new stainless flange head screws matt black and fitted everything back into the dashboard. I think this is an improvement on the original design and very sturdy, without looking out of place!

|

Edited by - AAA on 13 Sep 2021 11:17:12 |

|

|

|

AAA

49 Posts |

Posted - 11 Sep 2021 : 19:17:44 Posted - 11 Sep 2021 : 19:17:44

|

| Thanks very much for the kind and positive comments and PMs I have received. I hope this is of interest, plenty more to come! |

|

|

|

Panky

United Kingdom

70 Posts |

Posted - 10 Sep 2021 : 21:09:33 Posted - 10 Sep 2021 : 21:09:33

|

Really enjoying this thread and admire your skills and inprovisation techniques - cheese grater, who would have thought of that . Some superb results being produced. . Some superb results being produced. |

|

|

|

AAA

49 Posts |

Posted - 10 Sep 2021 : 19:47:37 Posted - 10 Sep 2021 : 19:47:37

|

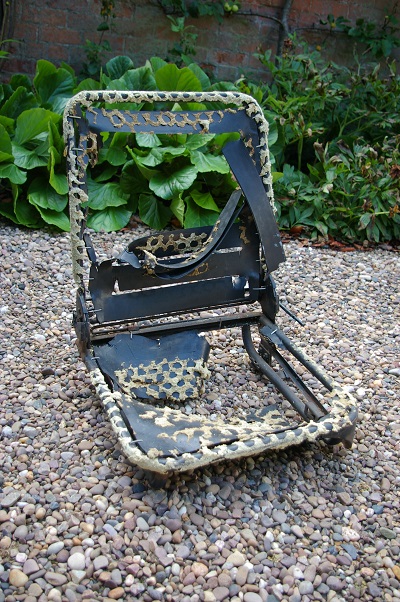

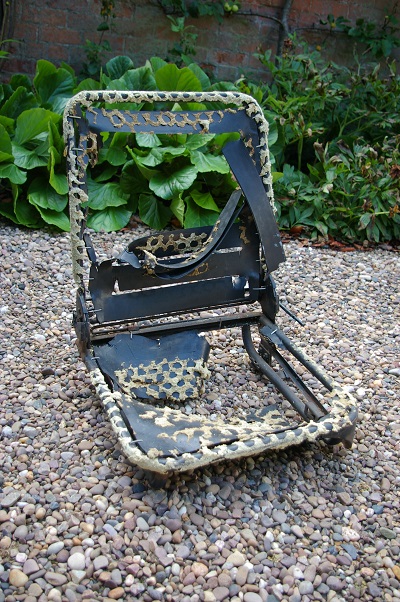

FRONT SEATS

I had managed to get hold of four front seats. All had damaged covers and failed rubber diaphragms. One seat had been professionally repaired at some point in the past, with some parts replaced with a different type of vinyl.

I stripped all four seats back to the frames. The frames were rusty and the foam cushions were breaking up.

I selected what appeared to be the best pair of frames. These were de-rusted and cleaned back to bare metal. I found one frame to be cracked, so this was welded. I then sprayed the prepared frames with anti-rust primer, black primer and several coats of black satin finish Hammerite.

All of the covers were damaged. I unpicked most of the stitching and used sections from all four seats to make up a full set of covers. I cleaned and repaired any slight damage on each section before stitching everything together. I strengthened the edges of the covers, (where they are clipped over the frames) using a pre-glued iron-on fabric tape. Making up the covers was a slow job, taking a number of evenings to complete.

None of the seat foams were useable. They were leaving crumbs, were hard and brittle in places, and were covered in old glue. I bought new 6" thick blocks of high density upholstery foam, choosing a foam which was slightly firmer than the original, (as I suspect the originals have lost some of their structure).

Using the best survivors as templates, I marked out the shapes with a felt pen, making the new foam slightly bigger but also measuring the insides of the covers to be sure. Using an electric carving knife I cut the foams roughly to shape, being careful not to remove too much material.

The foam was then finished using a large box cheese grater, (finest side) and a rubber-backed fine sanding disc in the electric drill. I tried using a coarse sanding disc, but this had a tendency to grab and snatch at the foam. Each foam took about two hours to shape from start to finish.

I replaced the seat diaphragms with Pirelli webbing, (the wider 2" heavy duty type). I made use of as many existing holes in the frames as possible so as to limit how many additional holes had to be drilled. I used a gasket punch for the end staples to ensure a neat hole in the webbing and reduce any chance of the end staples pulling through. The straps have to be made shorter and stretched into position.

Originally, the seats were assembled using large quantities of glue. I reassembled them using glue only where necessary to make them easier to repair in the future. I avoided using glue on the covers, pulling the shaping in using loops of thread passed through the seat foams and tied behind through thin plastic spreader plates. These are hidden behind the Pirelli straps. I replaced all of the four-prong cover retaining clips with a two-prong type, again making it easier to take the seats apart in the future. These also do much less damage to the edges of the covers when removed.

According to the workshop manual the seat runners cannot be taken apart for service and repair, this isn't true! By bruising down the pressing on the inside of each runner at the back, they slide apart. Inside each are two steel rollers, each with two rubber tyres. I cleaned these up, removing a lot of dirt and old grease. When reassembling, grease only needs to be applied to the sides where the rollers can rub and the very edges of the top runner, the rest can be left dry. The various plastic knobs and lever finishers were cleaned, with any roughness or scratches removed using abrasive paper. These were then polished and refitted. I put the seats to one side rather than fitting them to the car so as to make it easier to work on the dashboard. |

Edited by - AAA on 10 Sep 2021 19:49:02 |

|

|

|

AAA

49 Posts |

Posted - 08 Sep 2021 : 20:19:23 Posted - 08 Sep 2021 : 20:19:23

|

DOOR & REAR QUARTER PANELS

I had been given one set of side panels, with one additional driver's door panel.

The rear quarters were in generally good condition. These were cleaned in the same way as the rear seat. They had a couple of small splits, I strengthened these from behind using aluminium tape, (which is very thin and very sticky). I then glued the edges with PVA, holding these in position with masking tape to dry overnight. I used a very small amount of heavy duty leather and vinyl filler where needed. One panel had several small pin holes, (possibly caused years ago by welding spatter) these were repaired in the same way. I replaced the waist seal with new. These are narrower than those commonly used, but Woolies have the correct type available. The bends are easy to put in by hand. I replaced the plastic retaining clips, (most were missing or broken).

The door panels were quite warped. After cleaning, I saturated the backs with hot water and pressed the panels between two pieces of woodblock worktop I had in the garage, piling a couple of toolboxes on top. I put an offcut of vinyl flooring in to protect the visible face of each panel. I left them for three days, then removed them and laid them flat for any remaining moisture to dry off for a couple more days. I repaired any small nicks/splits using aluminium tape and leather filler. The carpet sections were carefully unstitched using a scalpel to cut through the thread. The bottom edge is made from fabric-strengthened vinyl, but the rest of the panel is very thin and fragile vinyl with no strengthening, extra care was needed along the top edge of the carpet. I cut new carpet and stitched this in by hand, using the original stitching holes in the vinyl so as not to weaken it. I then used spray glue to fix the carpet to the hardboard panel and stapled the edges back over using staples with very short legs, (the same as the originals).

The next challenge was to improve the chrome bands on the panels. These were dull is some places and peeling in others. Firstly, I tried using wide chrome stripe tape, ordered cheaply from China. This went on well, (on the third attempt) and bent around the curves well with a little heat. I then trimmed off the excess along the edges. A couple of hours later, the trial section had lifted off! This wasn't due to poor surface preparation, as the glue from the stripe tape was left behind on the panel, with none on the tape! I assumed the problem was down to poor quality tape, so ordered some from a UK supplier at three times the price...exactly the same thing happened again! Third time lucky...

I ordered a sheet of chrome vinyl wrap, the best sort I could find with an 8 year guarantee for exterior use! I cut this roughly to shape, and using gentle heat this pressed neatly over and around the edges and curves. I then careful cut along the edges with a sharp craft knife. With the cut started, a little tension on the end of the piece to be cut off and the lightest pressure on the knife left a neat and accurately cut edge. This material has stayed firmly in place. The surface has to be completely clean, with any peeling old material or roughness removed, as the wrap is very thin and any discrepancies in the surface show through.

The two driver's door panels I had both had damage on their rear edges, in the same places. There was a missing area of vinyl, with a ragged edge.

I used vinyl cut from the rear of the panel to repair this area, (there is quite a bit available on the backs where the final trimming of the material in the factory was not done very neatly). I put the replacement piece under the damage, then cut a half-moon shape through both the ragged edge and the new material underneath. This gave a neat butt joint. I fixed this together with aluminium tape and PVA glue, then a little leather filler. The filler dries matt, so in places the join was just visible. I used a little enamel lacquer with a fine paintbrush to match the graining across the filler, then stippled this with a moistened finger before it dried to take the gloss off.

New clips and waist seals finished the door panels.

The panels were fitted into the car. The rear quarters were slightly too deep, due to the new carpet and sound deadening. I cut a small strip of sound deadening out on each side before putting the carpet back over, this gave the panels enough clearance to drop and clip into place.

|

Edited by - AAA on 09 Sep 2021 09:38:09 |

|

|

|

AAA

49 Posts |

Posted - 06 Sep 2021 : 19:01:19 Posted - 06 Sep 2021 : 19:01:19

|

REAR SEAT

I was quite lucky here! I had managed to get a very good rear seat, with very little damage.

The base was in excellent condition, just needing a good clean. I cleaned up the spring unit underneath with a wire brush, and some small brushes in the rotary tool, finishing this with a few passes with a spray can. I cleaned the seat cover with cream cleaner and a scrubbing brush, followed by a soap solution and left it to dry in the sun. The cover had a few dents from storage, I gently heated these areas with a heat gun, they all smoothed out well.

The backrest was given the same treatment, but had a small area of stitching that had failed along the bottom edge, (normally they go along the top edge when they are exposed to the sun, but this one was fine in this area).

After a little more investigation, I found that the whole bottom edge needed sewing. I released the hog rings along the bottom edge and half way up each side. I was then able to peel the cover back. I hand-stitched the cover back together, using the original stitching holes and a pair of pliers to pull the needle through each time. Once all was done, I put the cover back in place and reattached it to the frame. I haven't used any additional products on the seat, just a good clean!

Something I would definitely recommend is the thread I have used throughout, IPCABOND bonded nylon thread 30s. This is the same thickness as that used originally. I haven't managed to break this yet, (although I have broken several needles, and cut through my own finger with it). It is supposedly rot proof and UV proof! |

|

|

Topic Topic  |

|

|

|